I had some scrap 7075-T6 aluminum left over from some other parts so I knocked off the corners until I could fit it into a collet. I then rough turned it down until is was round.

I had some scrap 7075-T6 aluminum left over from some other parts so I knocked off the corners until I could fit it into a collet. I then rough turned it down until is was round.

All posts by Tom

Hodgson Part 009/110, Cam Pad Support and Retainer Pad

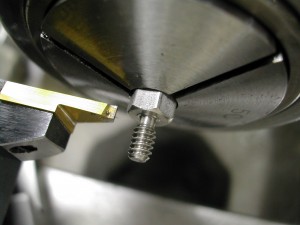

To save myself a little work, I used some stainless steel 6-32 hex threaded circuit board stand-offs to make the Cam Pad Supports. The spacers I bought were 18-8 SS, Male-Female, 1/4″ Hex, 6-32 Screw Size from McMaster-Carr, P/N 91075A444.

To save myself a little work, I used some stainless steel 6-32 hex threaded circuit board stand-offs to make the Cam Pad Supports. The spacers I bought were 18-8 SS, Male-Female, 1/4″ Hex, 6-32 Screw Size from McMaster-Carr, P/N 91075A444.

Hodgson Part 008, Cam Retainer Plate

Hodgson Part 007, Front Cover

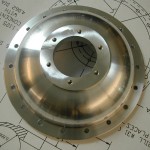

The front cover started life as a 125mm diameter by 300mm piece of Aluminum 7075-T6. I bought a stick of this long enough to make the cover, crankcase, rear seal plate, air guide, impeller, and a few fixtures. The diameter was needed to accommodate the crankcase so I did end up wasting a little material on the other parts.

The front cover started life as a 125mm diameter by 300mm piece of Aluminum 7075-T6. I bought a stick of this long enough to make the cover, crankcase, rear seal plate, air guide, impeller, and a few fixtures. The diameter was needed to accommodate the crankcase so I did end up wasting a little material on the other parts.

Hodgson Part 005, Bearing Retainer Plate

After almost a 2-year hiatus, I was able to restart the Hodgson project. I have a small machine shop in the lab where I work at Harvard so I have a little opportunity to play on nights and weekends.

I used a piece 2″ x 2″ square of 0.125″ of Aluminum 7075-T6 plate to make the front bearing retainer. A 3/8″ hole was drilled in the center of the piece to mount it to a scrap tooling plate in the mill vise, and the center of the part was zeroed.

I used a piece 2″ x 2″ square of 0.125″ of Aluminum 7075-T6 plate to make the front bearing retainer. A 3/8″ hole was drilled in the center of the piece to mount it to a scrap tooling plate in the mill vise, and the center of the part was zeroed.

Quorn Part 200, Wheelhead Collar

Quorn Part 104, Wheelhead Column

I had a slight problem when making my wheelhead column. I couldn’t find any competent machine shop with a 4-axis CNC mill to run the spiral groove. So, I needed to come up with a way that I could do it myself with the manual machines I had at my disposal. My gearhead lathe couldn’t cut a 2TPI thread so I had to find a way to make this part on the mill.

I had a slight problem when making my wheelhead column. I couldn’t find any competent machine shop with a 4-axis CNC mill to run the spiral groove. So, I needed to come up with a way that I could do it myself with the manual machines I had at my disposal. My gearhead lathe couldn’t cut a 2TPI thread so I had to find a way to make this part on the mill.

Quorn Parts 102/103, Bed Bars

Quorn Parts 100/101, The Bases

When dealing with castings, you have to remember that shrinkage, pattern mismatch, mis-located cores, and uneven surfaces can all contribute to making these parts hard to deal with. I was forewarned and ready to deal with the cored holes not being in the exact center of where the final holes needed to be, but when measuring the left base casting for my CAD model, I discovered that it was about 0.1″ short.

When dealing with castings, you have to remember that shrinkage, pattern mismatch, mis-located cores, and uneven surfaces can all contribute to making these parts hard to deal with. I was forewarned and ready to deal with the cored holes not being in the exact center of where the final holes needed to be, but when measuring the left base casting for my CAD model, I discovered that it was about 0.1″ short.

Quorn Split Cotters

Like many others building Quorns, I decided to incorporate split cotters instead of splitting the castings as envisioned by Chaddock. One of the major problems with Chaddock’s design is the tendency for the painstakingly bored and lapped holes in the castings to close up when the casting is split and no longer allow the shafts to move freely.

Like many others building Quorns, I decided to incorporate split cotters instead of splitting the castings as envisioned by Chaddock. One of the major problems with Chaddock’s design is the tendency for the painstakingly bored and lapped holes in the castings to close up when the casting is split and no longer allow the shafts to move freely.