Finding high quality materials here in China is a problem so I’m always looking outside-the-box to find materials for my parts. For these tappets, I ended up killing three birds with one stone. By using some hardened dowel pins from McMaster-Carr, I ended up with quality steel, a ground surface finish to ride against the bronze tappet bushings, and a hard material to ride against the cam ring.

Finding high quality materials here in China is a problem so I’m always looking outside-the-box to find materials for my parts. For these tappets, I ended up killing three birds with one stone. By using some hardened dowel pins from McMaster-Carr, I ended up with quality steel, a ground surface finish to ride against the bronze tappet bushings, and a hard material to ride against the cam ring.

All posts by Tom

Hodgson Part 025, Tappet Bushings

The plans call for regular brass for the tappet bushings, but I decided to use sintered bronze bushings (McMaster-Carr P/N 6391K116) as my starting point. These are 3/16″IDx5/16″ODx1/2″LG SAE841 oil-impregnated, sintered bronze bushings.

The plans call for regular brass for the tappet bushings, but I decided to use sintered bronze bushings (McMaster-Carr P/N 6391K116) as my starting point. These are 3/16″IDx5/16″ODx1/2″LG SAE841 oil-impregnated, sintered bronze bushings.

Hodgson Part 024/069 Cylinder Studs & Value Adjusters

I’ve combined the cylinder studs and the valve adjusters on one page because they are practically the same thing. I bought one box of #4-40×3/4″ 18-8 stainless set screws from McMaster-Carr (P/N 92311A113). For the cylinder studs, the socket end was cut off and rounded. For the valve adjusters, the cup end was cut off and rounded.

I’ve combined the cylinder studs and the valve adjusters on one page because they are practically the same thing. I bought one box of #4-40×3/4″ 18-8 stainless set screws from McMaster-Carr (P/N 92311A113). For the cylinder studs, the socket end was cut off and rounded. For the valve adjusters, the cup end was cut off and rounded.

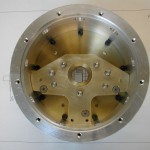

Hodgson Part 023, Housing

The crankcase started life as a 125mm diameter by 300mm piece of Aluminum 7075-T6. I bought a stick of this long enough to make the front cover, crankcase, rear seal plate, air guide, impeller, and a few fixtures. The diameter was needed to accommodate the crankcase so I did end up wasting a little material on the other parts. To make the crankcase, I sawed off a 4.75″ section so I could move everything closer to the chuck.

The crankcase started life as a 125mm diameter by 300mm piece of Aluminum 7075-T6. I bought a stick of this long enough to make the front cover, crankcase, rear seal plate, air guide, impeller, and a few fixtures. The diameter was needed to accommodate the crankcase so I did end up wasting a little material on the other parts. To make the crankcase, I sawed off a 4.75″ section so I could move everything closer to the chuck.

Hodgson Part 022, Rear Main Bearing

For the rear bearing, I chose C63000 nickel aluminum bronze (known as QAL9-4 bronze here in China). This material has high strength because of the added nickel (needed for the thin mounting flange) and good wear resistance. The downside is this material is very “grabby” and tends to warp if you get it hot. Therefore, I’m going to machine it in two phases with a stress relieving operation in-between.

For the rear bearing, I chose C63000 nickel aluminum bronze (known as QAL9-4 bronze here in China). This material has high strength because of the added nickel (needed for the thin mounting flange) and good wear resistance. The downside is this material is very “grabby” and tends to warp if you get it hot. Therefore, I’m going to machine it in two phases with a stress relieving operation in-between.

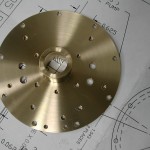

Hodgson Part 021, Front Bearing

For the front bearing, I chose C63000 nickel aluminum bronze (known as QAL9-4 bronze here in China). This material has high strength because of the added nickel (needed for the thin mounting flange) and good wear resistance. The downside is this material is very “grabby” and tends to warp if you get it hot. Therefore, I’m going to machine it in two phases with a stress relieving operation in-between.

For the front bearing, I chose C63000 nickel aluminum bronze (known as QAL9-4 bronze here in China). This material has high strength because of the added nickel (needed for the thin mounting flange) and good wear resistance. The downside is this material is very “grabby” and tends to warp if you get it hot. Therefore, I’m going to machine it in two phases with a stress relieving operation in-between.

Hodgson Part 019, Cam Gear & Assembly

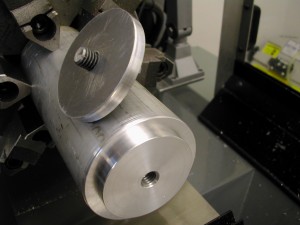

I turned a stub arbor with a 1/4″ thick aluminum washer to mount the brass gear for machining. You want a good tight fit on the ID of the gear. Continue reading

Continue reading

Hodgson Part 018, Cam Ring

Hodgson Part 014/015, Gears and Assembly

Hodgson Part 013, Jackshaft

I’ve mentioned before that obtaining quality material is one of my biggest problems here in China. Well, a corollary to that is that when I do have material, it’s probably not in the easiest-to-use form. For the jackshaft, I used a drop from a piece of 416 stainless plate that had been hardened to Rc35.

I’ve mentioned before that obtaining quality material is one of my biggest problems here in China. Well, a corollary to that is that when I do have material, it’s probably not in the easiest-to-use form. For the jackshaft, I used a drop from a piece of 416 stainless plate that had been hardened to Rc35.