Well, it would have been nice if I could have found some soft 1000-series aluminum here in China so I could just turn and part off these rings from some round stock, but that turned out to be impossible. I ended up purchasing some 0.032″ 1100 aluminum sheet. 1100 alloy is essentially pure aluminum and the 12″ x 12″ sheet I ordered from McMaster (p/n 2471T11) was in the “0” (Annealed) condition – perfect for a head gasket.

Well, it would have been nice if I could have found some soft 1000-series aluminum here in China so I could just turn and part off these rings from some round stock, but that turned out to be impossible. I ended up purchasing some 0.032″ 1100 aluminum sheet. 1100 alloy is essentially pure aluminum and the 12″ x 12″ sheet I ordered from McMaster (p/n 2471T11) was in the “0” (Annealed) condition – perfect for a head gasket.

Hodgson Part 056, Valve Seats

The Hodgson plans call for the valve seats to be made from Alloy 954 Aluminum Bronze (here in China this is called QAL 9-4 bronze or C63000 nickel aluminum bronze). These valve seats are retained in the head only by a 0.002″ interference press fit. Retention by only a press fit between components subject to heating and cooling cycles between two materials having different coefficients of thermal expansion is a problem waiting to happen in my opinion. I wanted a Continue reading

The Hodgson plans call for the valve seats to be made from Alloy 954 Aluminum Bronze (here in China this is called QAL 9-4 bronze or C63000 nickel aluminum bronze). These valve seats are retained in the head only by a 0.002″ interference press fit. Retention by only a press fit between components subject to heating and cooling cycles between two materials having different coefficients of thermal expansion is a problem waiting to happen in my opinion. I wanted a Continue reading

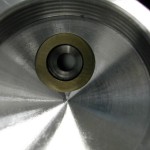

Hodgson Part 055, Heads

This page is one of the longest in the Hodgson Radial log and probably reflects that this is one of the most complex parts. I chose Aluminum 7075-T651 for the head material and made a few changes to the process plan and the design of the head – most notably the method of retaining the valve seats. Follow along on this lengthy build log as I start construction of 11 heads.

This page is one of the longest in the Hodgson Radial log and probably reflects that this is one of the most complex parts. I chose Aluminum 7075-T651 for the head material and made a few changes to the process plan and the design of the head – most notably the method of retaining the valve seats. Follow along on this lengthy build log as I start construction of 11 heads.

Hodgson Part 051/052, Wrist Pins & Buttons

For the full floating wrist pins, I started with some 12L14 unhardened precision ground shafting from McMaster-Carr. This shafting, p/n 1327k52, has a diametrical tolerance of +0.0000″ to -0.0002″ with a 10rms surface finish. The aluminum rivets used for the buttons were also purchased from McMaster (p/n 94439A330).

For the full floating wrist pins, I started with some 12L14 unhardened precision ground shafting from McMaster-Carr. This shafting, p/n 1327k52, has a diametrical tolerance of +0.0000″ to -0.0002″ with a 10rms surface finish. The aluminum rivets used for the buttons were also purchased from McMaster (p/n 94439A330).

Hodgson Part 050, Pistons

For my pistons, I chose to use silicon/nickel aluminum, alloy 4032-T6 because of it’s high wear resistance. This material is commonly used for brake master cylinders and forged pistons. I was able to purchase some 26mm diameter material, which worked out just fine for the 1.000″ finished O.D. of the pistons.

For my pistons, I chose to use silicon/nickel aluminum, alloy 4032-T6 because of it’s high wear resistance. This material is commonly used for brake master cylinders and forged pistons. I was able to purchase some 26mm diameter material, which worked out just fine for the 1.000″ finished O.D. of the pistons.

Hodgson Part 048, Slave Rod Pins

Finally, a nice simple part if you ignore the 0.018″ snap ring grooves. I started with some 12L14 unhardened precision ground shafting from McMaster-Carr. This shafting, p/n 1327k52, has a diametrical tolerance of +0.0000″ to -0.0002″ with a 10rms surface finish.

Finally, a nice simple part if you ignore the 0.018″ snap ring grooves. I started with some 12L14 unhardened precision ground shafting from McMaster-Carr. This shafting, p/n 1327k52, has a diametrical tolerance of +0.0000″ to -0.0002″ with a 10rms surface finish.

Hodgson Part 047, Slave Rods

The slave rods were made from a piece of aluminum 7075-T651 sawn from plate.

Here’s the material sawn up for the master rod and the slave rods. Everything was sawn about 0.1″ oversize in all dimensions to all for clean up.

Here’s the material sawn up for the master rod and the slave rods. Everything was sawn about 0.1″ oversize in all dimensions to all for clean up.

Hodgson Part 046, Main Rod Bearing

The main rod bearing was a purchased SAE660 bronze sleeve bearing p/n 6381K528 available from McMaster-Carr. It has the correct I.D., but the O.D. is larger and the length is a little long as well.

First step is to make a little 9/16″ expansion arbor to hold the bushing for machining. This was a scrap piece of aluminum tapped with a 1/8″ pipe thread and then split with a hacksaw while still chucked in the collet.

First step is to make a little 9/16″ expansion arbor to hold the bushing for machining. This was a scrap piece of aluminum tapped with a 1/8″ pipe thread and then split with a hacksaw while still chucked in the collet.

Hodgson Part 045, Master Rod

The master rod was made from a piece of aluminum 7075-T651 sawn from plate.

The master rod was made from a piece of aluminum 7075-T651 sawn from plate.

One master rod and ten slave rod blanks ready for squaring.

Hodgson Part 043, Impeller

The impeller started life as a 125mm diameter by 300mm piece of Aluminum 7075-T6. I bought a stick of this long enough to make the front cover, crankcase, rear seal plate, air guide, impeller, and a few fixtures. The diameter was needed to accommodate the crankcase so I did end up wasting a little material on the other parts.

The impeller started life as a 125mm diameter by 300mm piece of Aluminum 7075-T6. I bought a stick of this long enough to make the front cover, crankcase, rear seal plate, air guide, impeller, and a few fixtures. The diameter was needed to accommodate the crankcase so I did end up wasting a little material on the other parts.