With the process of getting the new engine connected, I discovered one item that had been previously overlooked. The stock thermostat housing exited straight up and would have caused the upper radiator hose to interfere with the turbocharger air inlet hose. Obviously a solution was needed, and that solution turned out to be a custom thermostat housing that exited to the side.

With the process of getting the new engine connected, I discovered one item that had been previously overlooked. The stock thermostat housing exited straight up and would have caused the upper radiator hose to interfere with the turbocharger air inlet hose. Obviously a solution was needed, and that solution turned out to be a custom thermostat housing that exited to the side.

Tig Rod Holder

Engine is Ready

The new engine is ready for installation, and the backhoe engine bay is ready to receive it. Both of the new front motor mounts are welded in, the old motor mounts have been removed, and new hose managers installed.

The new engine is ready for installation, and the backhoe engine bay is ready to receive it. Both of the new front motor mounts are welded in, the old motor mounts have been removed, and new hose managers installed.

While waiting on the weather to cooperate so I can install the engine, I got started on the new exhaust system. On a car, this would be called the turbo “down”pipe . Here, it exits straight up and a 5” cherry-bomb muffler will slip over the end. Everything is tacked for the moment until I can verify the position once the engine is installed in the backhoe.

While waiting on the weather to cooperate so I can install the engine, I got started on the new exhaust system. On a car, this would be called the turbo “down”pipe . Here, it exits straight up and a 5” cherry-bomb muffler will slip over the end. Everything is tacked for the moment until I can verify the position once the engine is installed in the backhoe.

Springtime Distractions Redux

And these are the cold frames two days later. Lisa did not even get a chance to put plants in her new raised beds before we had a little bit of a windstorm and one of the NEIGHBOR’S trees fell on the cold frames.

And these are the cold frames two days later. Lisa did not even get a chance to put plants in her new raised beds before we had a little bit of a windstorm and one of the NEIGHBOR’S trees fell on the cold frames.

Not a single sash on the rear box escaped damage. Panes were knocked out of all four sashes; both sides of the cold frame got hit. One picket in the bee screen was broken as well so it looks like I’ll be spending a little more time on the garden.

Not a single sash on the rear box escaped damage. Panes were knocked out of all four sashes; both sides of the cold frame got hit. One picket in the bee screen was broken as well so it looks like I’ll be spending a little more time on the garden.

Bigger bite for a little saw

I do a little tree climbing, and the saw I take in the tree with me is a Stihl MS192T. It’s a great little saw, not as powerful at the MS200T, but enough to do what I need. However one shortcoming it has is the integral plastic bucking spike. The plastic teeth are too short, ill shaped, and just plain too dull to dig into the bark.

While browsing the parts manual for this saw, I noticed one of the images showed a separate bucking spike and chain catcher. The spike part number is 1129 664 0500, and you’ll also need two of the special screws, PN 9074 477 4130.

While browsing the parts manual for this saw, I noticed one of the images showed a separate bucking spike and chain catcher. The spike part number is 1129 664 0500, and you’ll also need two of the special screws, PN 9074 477 4130.

Springtime Distractions

With the April Showers tapering off, the end of Mud Season is here! The last couple of weekends have had a few other projects distracting me from my backhoe engine work. First up is a nice little birdbath made from an aromatic cedar log a friend gave Lisa.

I chainsawed a slot up the side of the post, and cut a recess in the top so that when winter arrives, we can place one of the ugly, but integrally heated, plastic birdbaths on the post. For now, we’ll get to enjoy this whimsical glass butterfly bowl. I hope our birds and bees like it too.

I chainsawed a slot up the side of the post, and cut a recess in the top so that when winter arrives, we can place one of the ugly, but integrally heated, plastic birdbaths on the post. For now, we’ll get to enjoy this whimsical glass butterfly bowl. I hope our birds and bees like it too.

Fabricated Parts & Motor Mounts

SolidWorks 2014 Perkins Fabricated Parts (17.5M)

In addition to the bellhousing, quite a number of other parts needed to be fabricated before the engine was ready to be installed. The Perkins came without electrics, and the old Iveco starter would not fit the new engine. A new starter was purchased, but I was able to use the old alternator by fabricating a new mount.

Flywheel Modifications

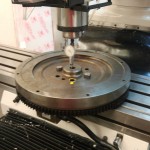

With the bellhousing finished, it was time to move on to the flywheel. This 76lb chunk of cast iron needed to be modified to maintain the same setback (bellhousing flange to flywheel face) dimension as the Iveco setup. The pilot bore needed to be changed to fit the transmission torque converter, and new mounting holes for the flex plate needed to be drilled and counterbored.

With the bellhousing finished, it was time to move on to the flywheel. This 76lb chunk of cast iron needed to be modified to maintain the same setback (bellhousing flange to flywheel face) dimension as the Iveco setup. The pilot bore needed to be changed to fit the transmission torque converter, and new mounting holes for the flex plate needed to be drilled and counterbored.