Details 03 & 05, the Spindle and Wheel Nut

After finishing the Tool Holder Head and Arm, I tackled the Spindles next. I need to fit the Spindle Housings to the Tool Holder Head, and in order to make the spindle housings, I need to finish the Spindles first. And, I’ll need the nuts to check the spindle threads. So nuts first and this time I don’t have to start with squaring up round stock. I’ve turned about an inch of 1/2″ 17-4 H1150 down to 0.440″. This is just larger than across the diagonal of the 3/8″ nut. This was followed by drilling and tapping 1/4-28.

After finishing the Tool Holder Head and Arm, I tackled the Spindles next. I need to fit the Spindle Housings to the Tool Holder Head, and in order to make the spindle housings, I need to finish the Spindles first. And, I’ll need the nuts to check the spindle threads. So nuts first and this time I don’t have to start with squaring up round stock. I’ve turned about an inch of 1/2″ 17-4 H1150 down to 0.440″. This is just larger than across the diagonal of the 3/8″ nut. This was followed by drilling and tapping 1/4-28.

NOTE: After using the tool for a while, I noticed the lower knurl and nut loosening during use. I remade the lower spindle and nut with left-hand threads to keep this from happening.

Next, face of the end and part off at about 0.130″. Face, part off. Rinse, repeat. I had enough stock turned down so I went ahead a parted off an extra blank. I also make a quick jig out of some scrap aluminum. It’s just a 1/2″ slug, faced on both ends with a 0.251″ hole through the center. A 1/4-28 cap screw and nut will hold the nut blanks for further machining.

Next, face of the end and part off at about 0.130″. Face, part off. Rinse, repeat. I had enough stock turned down so I went ahead a parted off an extra blank. I also make a quick jig out of some scrap aluminum. It’s just a 1/2″ slug, faced on both ends with a 0.251″ hole through the center. A 1/4-28 cap screw and nut will hold the nut blanks for further machining.

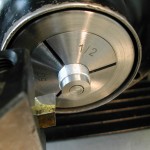

The jig is first used in the lathe to face off the unfinished side of the nuts to the final thickness of 0.125″.

The jig is first used in the lathe to face off the unfinished side of the nuts to the final thickness of 0.125″.

The the jig and 5C collet are moved to the mill in a collet block and the hex is formed on the nut. Rinse and repeat for the other nut and any spares.

The the jig and 5C collet are moved to the mill in a collet block and the hex is formed on the nut. Rinse and repeat for the other nut and any spares.

Then its back to the lathe to add a 30° chamfer to each side of the nut to finish them off.

Then its back to the lathe to add a 30° chamfer to each side of the nut to finish them off.

Michael used tool steel for his spindles and hardened the end that ran in the brass bushing. I never have very good luck with hardening, so I’m going to work in the opposite direction. I’m starting with 5/16″ hardened alloy steel dowel pins. I’ll use carbide tools to machine the spindle from these dowel pins in the hardened state, although I plan on tempering the area where I’ll be threading. It’s relatively easy to take hardness out of steel.

Michael used tool steel for his spindles and hardened the end that ran in the brass bushing. I never have very good luck with hardening, so I’m going to work in the opposite direction. I’m starting with 5/16″ hardened alloy steel dowel pins. I’ll use carbide tools to machine the spindle from these dowel pins in the hardened state, although I plan on tempering the area where I’ll be threading. It’s relatively easy to take hardness out of steel.

One of the keys to hard-turning and hard-milling with carbide is rigid setups. If the part or cutter can move, the carbide will chip and you’ll start rubbing instead of cutting. There’s no way I’d be able to mill the hex on the end of a 1/2″ long ø3/16″ post vibrating in the wind. So, I’m going to face off the end and rough turn a short section down to 0.195″. This is slightly larger than across the diagonal of the larger 5/32″ hex I’m going to use.

One of the keys to hard-turning and hard-milling with carbide is rigid setups. If the part or cutter can move, the carbide will chip and you’ll start rubbing instead of cutting. There’s no way I’d be able to mill the hex on the end of a 1/2″ long ø3/16″ post vibrating in the wind. So, I’m going to face off the end and rough turn a short section down to 0.195″. This is slightly larger than across the diagonal of the larger 5/32″ hex I’m going to use.

A quick trip to the mill and the larger 5/32″ hex is milled on both spindles.

A quick trip to the mill and the larger 5/32″ hex is milled on both spindles.

Back in the lathe, the bearing ends are turned down to 0.1872″-0.1870″ to make a light push fit on the ball bearings. Sharp cutters and lots of coolant to keep from tempering the part are the keys here.

Back in the lathe, the bearing ends are turned down to 0.1872″-0.1870″ to make a light push fit on the ball bearings. Sharp cutters and lots of coolant to keep from tempering the part are the keys here.

The spindles are flipped, the over-all-length is faced 0.005″ long and then the knurl ends are turned 0.005″ oversize and 0.005″ short of the shoulder length.

The spindles are flipped, the over-all-length is faced 0.005″ long and then the knurl ends are turned 0.005″ oversize and 0.005″ short of the shoulder length.

A scrap of aluminum with a 0.1875″ reamed hole acts as a heat sink to keep from tempering the bearing end while the knurl end is heated with a propane torch. A good blue means they should be soft enough that we won’t break the sharp tip off of the threading tool.

A scrap of aluminum with a 0.1875″ reamed hole acts as a heat sink to keep from tempering the bearing end while the knurl end is heated with a propane torch. A good blue means they should be soft enough that we won’t break the sharp tip off of the threading tool.

Now, turn the final 0.250″ diameter so it is a slip fit on the knurls you’ll be using and face the OAL and shoulder to the finish lengths. I’ve also turned the thread area down to 0.246″ major thread diameter. You can see the surface finish in this softer area is not near as nice as in the rest of the hardened pin.

Now, turn the final 0.250″ diameter so it is a slip fit on the knurls you’ll be using and face the OAL and shoulder to the finish lengths. I’ve also turned the thread area down to 0.246″ major thread diameter. You can see the surface finish in this softer area is not near as nice as in the rest of the hardened pin.

A few passes with the threading tool and we have a passable 1/4-20 UNF-2A thread.

A few passes with the threading tool and we have a passable 1/4-20 UNF-2A thread.

Here’s a blurry photo of the finished spindles.

Here’s a blurry photo of the finished spindles.

Disclaimer and License

All material, including the CAD drawings, relating to the construction of the Cut Knurling Tool presented on this site is free to use any way you see fit. However, no guarantees are made regarding the accuracy or correctness of the material presented here.

Downloads

(CAD drawings are in SolidWorks 2013 Format)