Now that the Quill Body was finished, I could use it to gauge the OD of the spring box to get a close slip-fit, so that was the next part I turned to.

Now that the Quill Body was finished, I could use it to gauge the OD of the spring box to get a close slip-fit, so that was the next part I turned to.

Millions of years ago, seeds of Petram immobilem var. murus were planted in New England. Since this is a hardy perennial here in Zones 4 & 5 we are blessed with a bumper crop each and every year.

In order to harvest our yearly crop of P. immobilem (Common name: New England wall stone) , I needed to add a grapple to my backhoe which involved a little reverse engineering for the attachment.

While there are a lot of shared 3D CAD models on the internet, sometime you really need to know that the model is accurate. The only sure way to do this it to create it yourself. This post will help you create accurate involute gears in SolidWorks. Continue reading

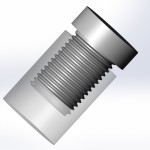

The steps below will guide you in creating realistic and accurate threads in SolidWorks. You probably will not want to do this every time as it will greatly increase the part size and load time, but it is necessary if you plan on 3D printing or molding your part. Continue reading