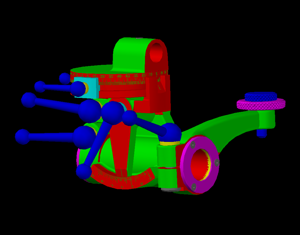

The Ball Handles

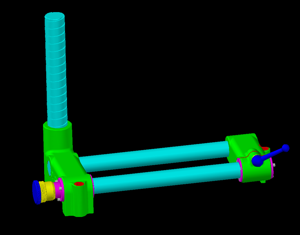

The Base

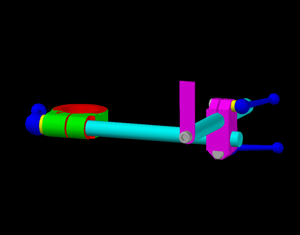

The Tooth Rest

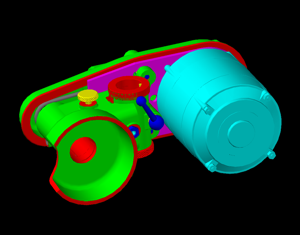

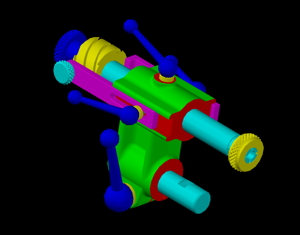

The Wheelhead

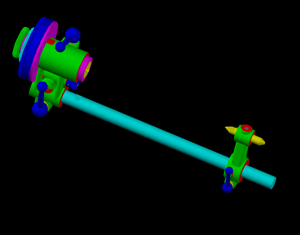

The Workhead

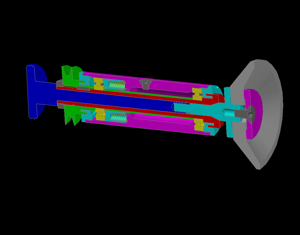

The Spindle

The Spiraling Toolholder

The General Purpose Toolholder

Martin Model 5C Spiraling Toolholder

Martin Model 5C General Purpose Toolholder

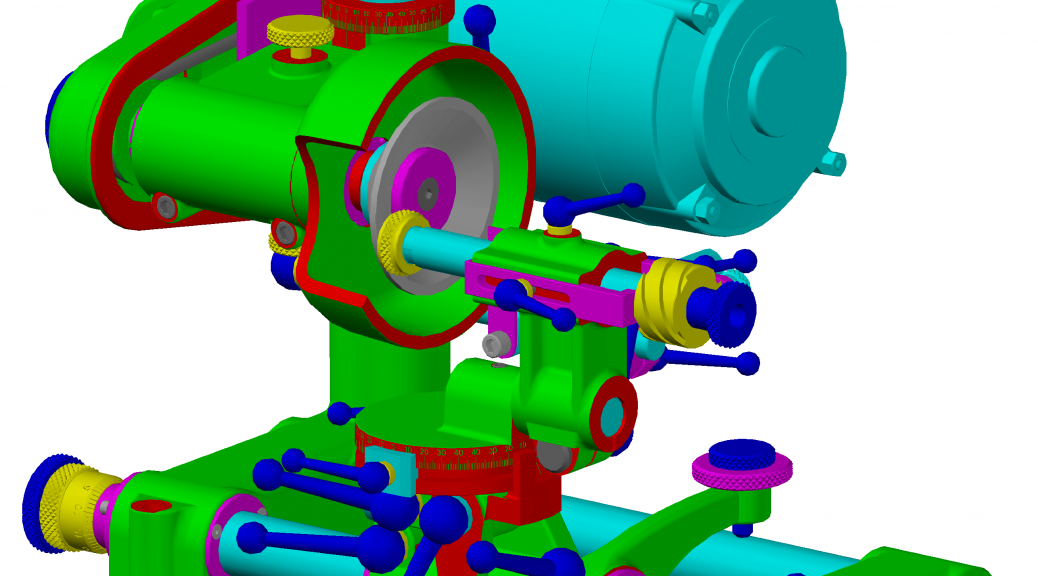

The Finished Quorn

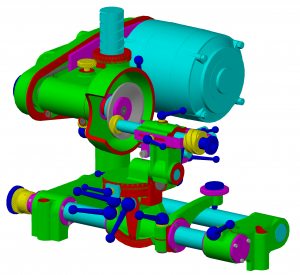

Overview

A tool and cutter grinder is used by machinists to create new cutting tools and sharpen old ones to remove metal when machining parts. In 1974 Professor D. H. Chaddock saw a need for an inexpensive tool and cutter grinder for the home hobby machinist and the Quorn TCG was born. The fabrication of the Quorn was originally covered in a series of articles in the British publication Model Engineering.

A tool and cutter grinder is used by machinists to create new cutting tools and sharpen old ones to remove metal when machining parts. In 1974 Professor D. H. Chaddock saw a need for an inexpensive tool and cutter grinder for the home hobby machinist and the Quorn TCG was born. The fabrication of the Quorn was originally covered in a series of articles in the British publication Model Engineering.

If you are interested in making your own Quorn, castings, plans, and a reprint of the original articles in book form are available from sources listed in the appendix.

Now that you know what a Quorn is, follow along as I attempt to turn some rough castings into a useful machine. Prior to cutting metal, I like to create a solid model of the parts in AutoCAD. For me, the process of creating the individual parts in CAD is very much like the machining process to fabricate the actual parts. I find that after making the CAD model, I have a much better understanding of the relationship between the individual parts, as well as very good understanding of the sequence of machining operations that will be needed to actually fabricate the part. My model is available for download.

Construction Logs

I’ve broken down the parts into groups much the same as Professor Chaddock. In each group, I’ll be creating pages for the individual parts documenting the fabrication of each part starting with the CAD model. On the left in each group is an image of the CAD model for that part group. Moving your mouse over the individual part links to the right of the image will highlight that part in the model. If the part has a construction log, you can click on the part number link to go to the log.

Guide to the construction logs below:

Finished parts have no decoration

• Denotes work in progress

~ Denotes pages coming soon

It’s been said that operating the Quorn is “like shaking hands with an octopus” because of the number of ball handles present on the machine. Fabricating the ball handles is a right of passage, so follow my ascension into the ranks of the worthy.

It’s been said that operating the Quorn is “like shaking hands with an octopus” because of the number of ball handles present on the machine. Fabricating the ball handles is a right of passage, so follow my ascension into the ranks of the worthy.

One significant change from Chaddock’s original design is my use of cotters instead of splitting the castings and using the ball handles to squeeze the split shut to allow adjustments. The cotter page details the creation of the cotters and the modifications made to the castings and design to accommodate them.

101 Right Base

102 Rear Bar

103 Front Bar

104 Wheelhead Column

~105 RH End Cap

~108 Micrometer Body

~109 Micrometer Thimble

~201 Bracket

~202 Belt Guard

~203 Wheel Guard

~206 Lifting Nut

~207 Index Pin

~208 Friction Pad

~209 Index Ring

~211 Motor Plate Bolt

~212 Belt Cover Screw

~213 Pivot Screw

~217 Adjusting Screw

~218 Motor Pulley

~220 Belt

~221 Motor

~301 Lever

~302 Tilting Bracket

~303 Rotating Base

~304 Thrust Washer

~306 Tee Bolt

~307 Stop

~308 Adjusting Screw

~312 Short Bed Bar

~500 Bracket

~501 Stop Bar

~502 Guide Bar

~503 Guide Pin

~504 Spindle

~505 Closing Ring

~506 Hob

~507 Hob Nut

~510 Bracket

~511 Collet Nut

~512 Split Collet

~513 Index Plate

~514 Back Plate

~516 Index Pin

~519 Index Knob

~523 Collet Spindle

~524 Spindle Draw Screw

~525 Morse Taper Arbor

~526 Dead Arbor

~527 Lock Collar

~529 Tailstock

~530 Tailstock Center

TO DO

- Martin Model 5C Spiraling Toolholder

- Martin Model 5C GP Toolholder

- Assembled Quorn Photos

Appendix

Following is the full list of Model Engineering articles covering the Quorn:

- A series called “Quorn Tool & Cutter Grinder” by D.H. Chaddock.

- 4 Jan 74, pp 19-22

- 18 Jan 74, pp 68-71

- 1 Feb 74, pp 121-124, 128

- 15 Feb 74, pp 185-189

- 1 Mar 74, pp 242-252

- 15 Mar 74, pp 289-292

- 5 Apr 74, pp 343-345

- 19 Apr 74, pp 385-388

- 3 May 74, pp 433 – 435

- 17 May 74, pp 484-487

- 7 Jun 74, pp 535-538

- 21 Jun 74, pp 580-583

- 5 Jul 74, pp 632-633, 659

- 19 Jul 74, pp 684-688

- 2 Aug 74, pp 736-740

- 16 Aug 74, pp 822-873

- 3 Dec 76, pp 1186-1190

- 17 Dec 76, pp 1288-1289

- “Tool & Cutter Grinding” by W.H. Thomas, beginning on page 965 in the 04 Oct 1974 issue.

- “Cutting a 1 inch pitch Thread” by John Warren, beginning on page 36 in the 03 Jan 1975 issue.

- “Thread Grinding on the Quorn” by W.M. Thomas, beginning on page 196 in the 21 Feb 1975 issue.

- “Tap Grinding on the Quorn” by W.M. Thomas, beginning on page 227 in the 07 Mar 1975 issue.

- “Grinding Staggered Tool Cutters” by W.M. Thomas, beginning on page 348 of the 04 April 1975 issue.

Quorn castings, plans, and the above articles reprinted in book form are available from the following sources (and probably others):

- Australia: Hobby Mechanics

- North America: Martin Model & Pattern

- U.K.: Model Engineering Services

CAD Files

AutoCAD 2008 Format

- Raw Castings 6.1M zip

- Common parts (locate one directory above component drawings) 2.6M zip

- Base (requires common parts) 7M zip

- Tooth Rest (requires common parts) 253K zip

- Wheelhead (requires common parts) 8.1M zip

- Workhead (requires common parts) 7.8M zip

- Spindle (requires common parts) 3.4M zip

- Spiraling Toolholder (requires common parts) 2.8M zip

- General Purpose Toolholder (requires common parts) 10.8M zip

- Assembled Quorn (requires all of the above) 68K zip

- 5C Spiraling Toolholder (TBD)

- 5C General Purpose Toolholder (TBD)

Disclaimer and License

All material, including the CAD drawings, relating to the construction of the Quorn presented on this site is free to use any way you see fit. However, no guarantees are made regarding the accuracy or correctness of the material presented here.