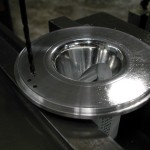

The carburetor mount was made from a 0.75″ x 1.3″ x 2.4″ piece of Aluminum 7075-T6, while the lock cylinder was made from Ø5/16″ yellow brass. I change the lock cylinder to a full split cotter, adjusted the outside perimeter of the carb mount to better match my rear cover casting, and reduced the size of the mounting studs to #10 to better fit the overall scale of the carb mount.

The carburetor mount was made from a 0.75″ x 1.3″ x 2.4″ piece of Aluminum 7075-T6, while the lock cylinder was made from Ø5/16″ yellow brass. I change the lock cylinder to a full split cotter, adjusted the outside perimeter of the carb mount to better match my rear cover casting, and reduced the size of the mounting studs to #10 to better fit the overall scale of the carb mount.